Center for Liquid Hydrocarbons developing nanotechnology for oil recovery

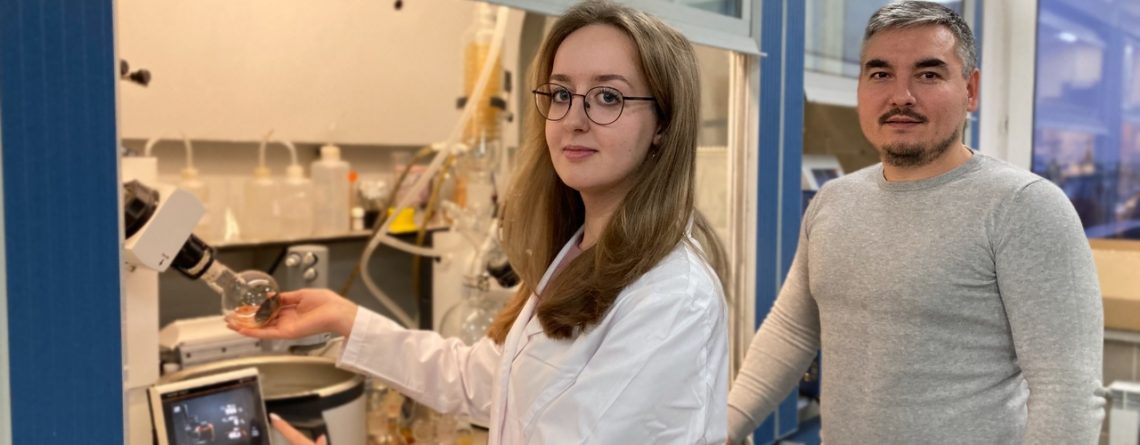

The Laboratory of Enhanced Oil Recovery has studied the influence of sodium metal nanoparticles on oil recovery.

Unfavorable geological conditions and low economic efficiency of oil production intensify innovation activities for the creation and further application of new technologies. Among the technological innovations are nanomaterials and nanotechnologies, in particular, organic dispersion of metallic sodium nanoparticles. It is mainly a question of application of this material for intensification of oil production from dense and poorly permeable reservoirs. This development of Kazanian scientists allows to obtain nanoparticles of an accessible but chemically very active material – metallic sodium – in a rather simple way. It can be easily injected into an oil-saturated reservoir, be activated and contribute to processes that increase the well flow rate. The publication saw light in Catalysts.

“Metallic sodium is a very active material that readily interacts with a variety of chemicals, and in reaction with water forms alkali and hydrogen gas. The first component, lye, has long been used in oil production, such as in alkaline flooding. Hydrogen gas, in turn, dissolves well in crude oil, increasing its mobility. Under certain conditions, metallic sodium promotes hydrogenation of unsaturated components, in addition, the contact of metallic sodium with water generates a large amount of heat, which together positively affects the well production rate,” said Alexey Vakhin, Lead Research Associate of the Laboratory of In-Situ Combustion.

Increasing demand for energy worldwide, the main source of which is hydrocarbon raw materials, consistently expands the need to create and implement innovative methods to increase oil recovery. The need to implement nanotechnology arises due to significant differences in production conditions, reservoir characteristics and properties of produced oils.

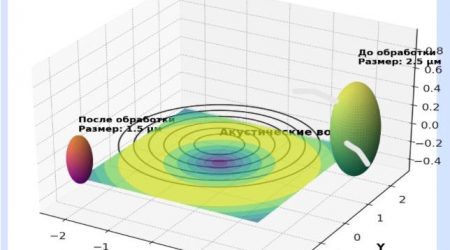

“Nanotechnology, which today covers many areas of industry and various spheres of human activity, has not bypassed the oil industry. It is known that moving to the nanoscale, where the particle size reaches the size of 1-100 nm, the proportion of surface atoms relative to bulk atoms increases sharply, and most processes in colloidal systems, which includes oil, take place at the interface, so the increase in surface area leads to the intensification of these processes. Consequently, nanoparticles are more reactive than their larger counterparts. In addition, due to their small size, nanoparticles can easily spread in porous media without reducing permeability,” explained Sofya Trubitsina, Engineer of the In-Situ Combustion Lab.

Despite the high efficiency demonstrated in various projects, nanoparticles are still quite an expensive resource. The cost of a particular solution based on nanotechnology depends primarily on the initial cost of precursors for synthesizing nanostructures. Therefore, this research is also aimed at reducing the cost and increasing the availability of nanoparticles for industrial solutions, which is certainly in line with the technological agenda of the modern world.

“We have been on the lookout for affordable and promising precursors of nanostructures that can effectively enhance the oil recovery of a reservoir with heavy oil. For the role of one of the candidates, in our opinion, metallic sodium is very well suited,” said Aidar Kayumov, Engineer of the Laboratory of Enhanced Oil Recovery.

“The first results of the study showed comparable efficiency of sodium organic uspensions with oil-soluble catalyst precursors, our earlier development. At the same time, the cost of obtaining sodium suspensions is much lower,” added Firdavs Aliyev, Senior Research Associate of the In-Situ Combustion Lab.