Fourth test conducted with UniCat catalyst in Samara Oblast

The In-Situ Combustion Lab continues its field testing in Samara Oblast.

Commissioned by RITEK, KFU scientists arrived at Aksyonov oil field on 22 November to organize a field test of a catalyst precursor based on iron, nickel, and cobalt. Lab Head Alexey Vakhin comments, “The effectiveness of this catalyst precursor in regard to oil refining was studied with physical and chemical methods.”

Senior Research Associate Irek Mukhamatdinov adds, “Based on previous laboratory and field tests we can conclude that thermal catalytic treatment improves physical and chemical properties of oil and recovery ratio. This new batch included 4.5 tons of catalyst and 6 tons of solvent.”

Engineer of the Section of Innovation Technologies and Strategic Projects of LUKOIL Engineering Alexander Protsenko notes, “The well uses a cyclic steam injection technology. Steam injection occurs in five days after catalyst injection.”

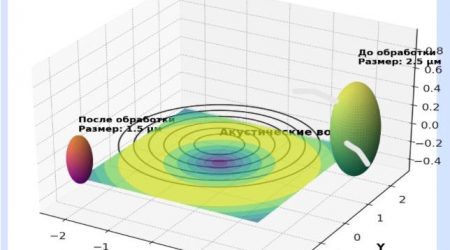

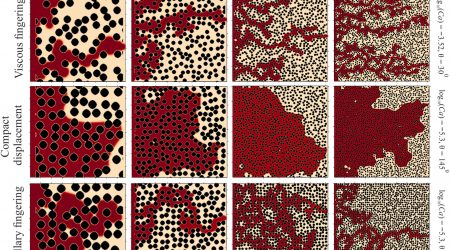

Previously, a catalyst precursor based on oil-soluble iron and nickel compounds was tested at a field in Samara Oblast. Observation results showed high efficiency of the reagent and allowed recommending it for further implementation at heavy oil fields. Based on the results of last year’s injection, an article was published in FUEL in co-authorship with employees of Ritek-Samara-Nafta and Lukoil Engineering. This research paper presents laboratory data on the effectiveness of the developed catalyst and the results of tests of field oil samples. Analysis of samples from the field after the catalyst injection showed that the phenomenon of destruction of high molecular weight paraffins under the action of catalysts is expressed in the reduction of viscosity of produced oil. Reduction of C20-C32 paraffins content has a positive effect on oil viscosity even at low temperatures. According to the dynamics of reduction of the share of high-molecular-weight paraffins, we can tentatively divide the contribution to the overall effect of viscosity reduction of the phenomena of in-situ destruction of tar and asphaltene compounds and C20-C32 paraffins. The obtained results show the possibility of using in-situ catalysts to improve the efficiency of development of high-viscosity paraffinic oil fields.

Speaking about the results of recent studies, the scientists note that during steam cyclic treatment without catalyst, six flushes of wells with light oil (140 m3) were carried out for 1 month to restore the performance of depth pumping equipment. In case of catalyst treatment no further flushes were required – the unit worked stably at the mode of maximum productivity of the equipment. Additional oil production for the analyzed period for the 2nd cycle of thermal steam treatment amounted to 883 tons, for the 1st cycle – 673 tons; oil viscosity decreased more than 4 times in comparison with the 1st cycle.

KFU catalysts have previously been tested at Boca de Jaruco (Cuba) and Ashalchi (Russia) fields.