Department of Petroleum, Gas and Carbon Materials Technology offers solutions for grape-based biofuels

The main disadvantage of currently existing technologies for bioethanol production using live microorganisms is the need for mandatory pretreatment of lignocellulosic feedstock to remove lignin. Nevertheless, there is no information on the complex technology of grape cake processing with obtaining biofuel (BTII) and products of high feed value, aimed at reducing the cost of the final product. The analysis of the previously developed basic technology for obtaining second-generation bioethanol (BTII) biofuel allowed to identify critical problems at the stages of enzymatic hydrolysis and alcoholic fermentation, the solution of which can significantly increase the efficiency of the process of obtaining second-generation fuel (bioethanol) and make it applicable for industrial production.

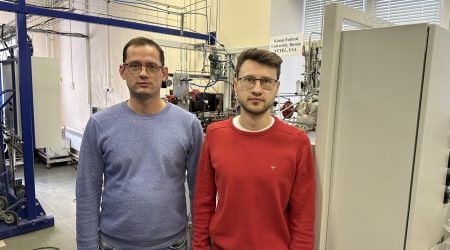

The authors of the biofuel project, Alim Kemalov and Ruslan Kemalov, found that the protein efficiency ratio of cellulosic bioethanol (second generation biofuel BTII) is 5 to 6 units compared to gasoline in its production, and its use can reduce the amount of greenhouse gases by 85%.

“Our BTII has a higher octane number (99 for motor and 105 for research method), lower combustion temperature and cleaner exhaust, as it does not contain sulfur compounds. bioethanol – BTII burns without ash formation, so the use of alcohol-containing blended gasoline does not cause the formation of deposits on the engine plugs, and thus its overheating does not occur,” explains Associate Professor Ruslan Kemalov.

The developers conducted a comprehensive analysis of the process of bioethanol BTII production on the basis of grape cake for the first time. Application of biostimulants of enzymatic hydrolysis allowed the authors to obtain an effective composition of nutrient medium. An integrated approach to the production of bioethanol BTII has been developed, and the novelty of technical solutions is confirmed by a Russian patent.

The development of alternative fuel energy will undoubtedly allow to save produced hydrocarbons, reduce the load on gas condensate production capacities in order to distribute them both in Russia and in Central Asian states.

“When processing grapes, such secondary products as grape cake, yeast and glue residue, and grape seeds are produced in significant volumes. Approximately 20% of each harvested ton of grapes is turned into grape cake. If the cake is left in heaps, residual juice will be released, including the rotting process of the cake, thus the residual liquid slowly leaking from the accumulated rotting squeeze will cause significant environmental damage. Getting into waterways promotes the development of fungus in wastewater,” the scientist explains.

Effective development of viticulture technologies in the field of processing of secondary products, oilcake will allow Russia to produce the world’s first bioethanol – BTII. Biotechnological transformation of lignin-cellulose-containing raw materials into bioethanol – BTII corresponds to the principles of circular economy and meets the concept of advanced development, so the demand for bioethanol from this type of raw materials is steadily growing. The volume of global bioethanol production reaches 86 billion liters per year. Lignocellulose is used as the main raw material for the production of bioethanol – BTII fuel, as it is the most available and cheapest raw material.

The work is being carried out in the Laboratory of Experimental Static Modeling of Petroleum, Gas and Carbon Materials.

The results have been reported at numerous scientific conferences; 2 patents of the Russian Federation, 20 articles in Russian journals and 10 articles in Q1-Q2 journals in Scopus and Web of Science databases have been published.