Research shows acetic acid salts simplify the production of heavy oil

Picture URL: https://pubs.acs.org/cms/10.1021/acs.iecr.3c04335/asset/images/medium/ie3c04335_0016.gif

KFU’s project is supported by the Russian Science Foundation.

According to the official website of the Russian Science Foundation, Kazanian scientists managed to find out that acetates – salts of acetic acid with transition metals – in combination with steam treatment reduce the viscosity of heavy oil by 58%. This approach was 19% more effective than steam alone, which is widely used in oil production. The proposed method will help to improve the energy efficiency of applied technologies. The results of the study, supported by a grant from the Presidential Program of the Russian Science Foundation, were published in Industrial & Engineering Chemistry Research.

Despite the desire to shift from fossil fuels to alternative energy sources, conventional oil and gas currently account for about 80% of energy consumption and serve as valuable petrochemical feedstocks. However, conventional oil is projected to run out in about 50 years, so oil producers are starting to use less accessible heavy oil. Due to the difficulties associated with extraction, the production of petroleum products based on heavy oil is very expensive. Moreover, the crude has to be additionally purified from high-molecular impurities – resins, asphaltenes, and others, which are contained in heavy oil in large quantities.

Most often superheated steam is injected into the reservoir to extract such oil. In this case, as a result of transition of steam to water, the formation heats up and oil becomes more mobile. This method of oil production is energy intensive, and to make it more efficient, it is possible to inject catalysts into the reservoir along with steam. These compounds ensure the elimination of the heaviest components of oil – resins and asphaltenes. This provides increased oil recovery of the reservoir, and the extracted oil is easier to transport and process.

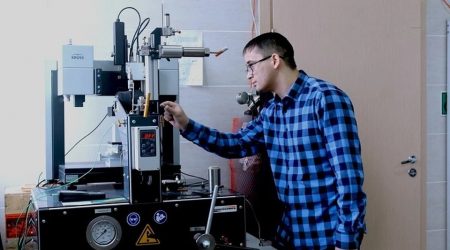

KFU scientists proposed to use salts of acetic acid with transition metals (acetates) as a supplement to steam treatment to reduce the viscosity of heavy oil. These compounds serve as catalyst precursors – sulfide particles of the corresponding transition metals are formed in the formation. They act as an active form of catalyst that affects the chemical bonds between carbon and sulfur in resins and asphaltenes.

First, the authors modeled the standard steam treatment of heavy oil samples in an autoclave. It turned out that this approach reduced the viscosity of the oil by 39%. Then the researchers added acetates of various metals – lead, magnesium, sodium, zinc, copper, and nickel – to the autoclave and compared the properties of oil that underwent such a combined (steam-catalyst) treatment with the results of the previous experiment, which used only steam. Acetates of copper and nickel, combined with the action of steam, reduced the viscosity of the original oil by 58%, which is 19% higher than the results of treatment with steam alone. This effect was achieved due to the fact that the catalyst accelerated the breakage of chemical bonds in the long molecules of resins and asphaltenes.

The authors proved that the amount of heavy high-molecular fractions in the oil really decreased by analyzing the chemical composition of oil before and after thermocatalytic action. It turned out that under the action of steam the share of heavy compounds decreased from 38% to 36%, while with the addition of nickel acetate – from 38% to 24%. The content of light hydrocarbons and aromatic compounds in this case increased by 14 percentage points (from 62% to 76%). These effects combined to produce a 58% reduction in viscosity.

“We have demonstrated for the first time that metal acetates can be used for steam-heat heavy oil extraction technologies. These inexpensive and safe compounds will help improve the energy efficiency of existing technology. In the future, we plan to conduct tests in conditions of a real oil-bearing reservoir to prove the possibility of using the proposed approach in practice,” says Firdaws Aliyev, Senior Research Associate of the Laboratory of In-Situ Combustion.

Source: Russian Science Foundation