Resource-saving technology of processing common reed waste helps to obtain bioethanol and cellulose-containing material

Cleaning of soil and artificial reservoirs from Phragmites reed overgrowth and rational utilization can reduce the environmental burden. At the same time, the newly formed biomass creates additional problems of environmental pollution, especially in regions with intensive agricultural activity. The problem of finding rational ways of qualified utilization of biomass, in particular, of common reed (CR) with obtaining valuable products remains very pertinent.

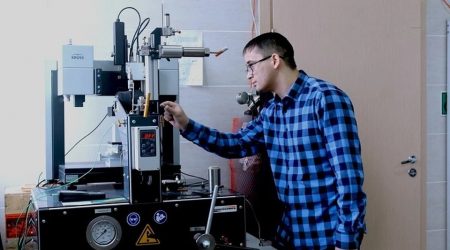

Employees of the Department of Oil, Gas and Carbon Materials Technology see a way to solve the problem of rational utilization of non-commercial biomass from cane by transforming it into commercial bioethanol. The development will not only reduce the production of petroleum gasoline and significantly reduce CO2 emissions in the residential and transportation sector, but also reduce environmental pollution in rural areas.

Proceeding from a number of peculiarities revealed as a result of the conducted researches on assessment of lignin properties, first of all, as a polymeric additive, it was expedient to consider it as a cellulose-containing component of stabilizing additive on the way of creation of crushed stone-mastic asphalt concrete (CMA) – a promising road-building material. In the course of operation this material is able to provide the normative index characterizing the flow of binder from the surface of stone material and high resistance to roadbed rutting. Thus, the accumulated arsenal of knowledge of composition, properties of hydrolyzed lignin, analysis of the results of their own research, allowed the authors to make prerequisites for the creation of waste-free integrated technology.

“In the work to improve the efficiency of the utilization process, modern physicochemical and biotechnological methods were used, which allow to alternately reduce the environmental burden through the formation and implementation of the obtained products and their further improvement”, says Associate Professor Ruslan Kemalov.

There are a lot of developments in the utilization of lignocellulosic wastes by chemical method. Some of them are devoted to the creation of sorbents for wastewater treatment and some solid fuels in the form of briquettes, etc. The achieved successes in scientific and applied research in domestic and world practice in the collection, preparation and processing of plant raw materials, namely, common reed, provide for the application of chemical and biotechnological methods in order to obtain valuable products – bioethanol and demanded materials for the road-building industry.

Professor Alim Kemalov and Associate Professor Ruslan Kemalov (Department of Oil, Gas and Carbon Materials Technology) have established that the transformation of local ecosystems into biofuel production will inevitably change the natural carbon balance and reduce the potential savings of greenhouse gas emissions; the inclusion of combined heat and power systems in the production of cellulosic ethanol will displace fossil fuels and provide a reduction in greenhouse gas emissions and increase the generation of cheaper electricity.

“Combined fuel cycle and vehicle life cycle analysis also shows significant reductions in greenhouse gas emissions, but not other emissions, when cellulosic ethanol is used as an alternative fuel. It is found that the use of bioethanol as a motor fuel can prevent up to 25% of CO2 emissions from petroleum gasoline emissions, considering the fossil fuel related energy consumed to grow and process the bio-crop. To compensate for 10% of CO2 emissions from gasoline consumption would require a fourfold increase in bioethanol production, i.e. 48% of arable land,” explains R. Kemalov.

The task of providing transportation fuel is to be able to replace the energy in harvested biomass with primary energy in fossil fuels. And it is important to do this without significant consumption of fossil energy. In this way, dedicated biomass plantations can displace about 15 % of the CO2 emissions expected from all uses of fossil fuels worldwide by 2030. This fact creates the preconditions for an intensive increase in the energy efficiency of the world economy.