Asphaltene structures studied with acoustic waves

The scientific team of the Institute of Geology and Petroleum Technologies of Kazan Federal University presented a unique development – an integrated method of calculation and reorganization of asphaltene structures in oil disperse systems under the influence of low-frequency acoustic waves of five kHz.

The paper saw light in Neftegaz.RU.

According to leading experts in the field of wave technologies, such as Professor Irik Fattakhov, Director for Enhanced Oil Recovery, Wave and Biotechnologies at TatNIPIneft Institute, wave action is a powerful and promising tool that should occupy an important place in modern oil production, treatment and transportation technologies. At the same time, as the professor emphasizes, its effective application requires a deep understanding of the mechanisms of wave impact on the reservoir and the development of intelligent solutions using AI and machine learning.

The author of the method is Alfayaad Assim Ghani Hashim, a PhD student of the Department of Oil, Gas and Carbon Materials Technology. The scientific supervisor was Ruslan Kemalov, associate professor of the department; and the scientific advisors were Alim Kemalov, chair of the department, and Dinar Valiev, senior lecturer of the department.

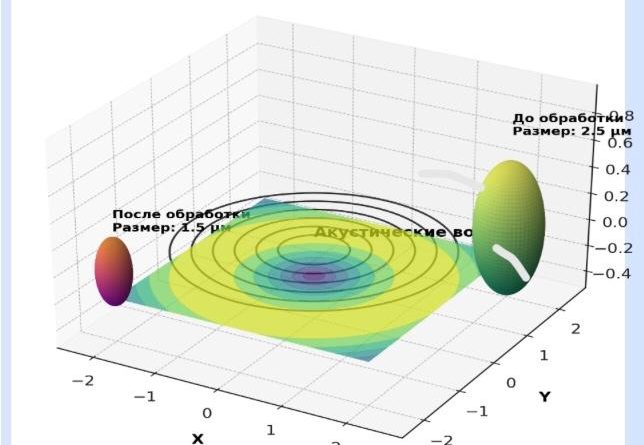

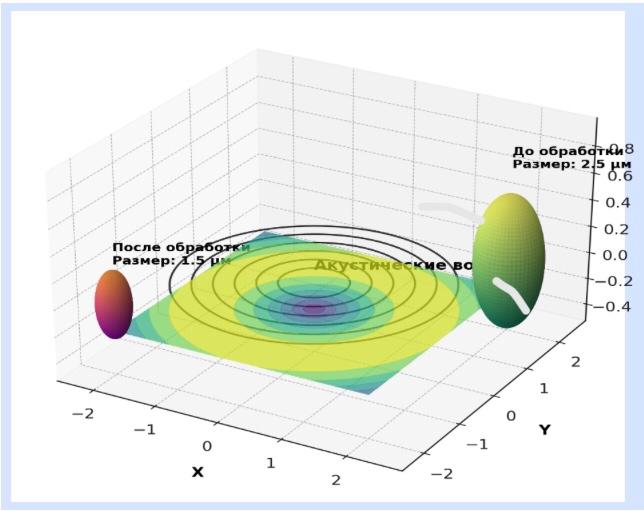

The development combines a multilevel approach, including methods of nuclear magnetic resonance (NMR-relaxometry), adsorption models Langmuir and BET, as well as diffusion analysis based on the Stokes-Einstein equation. This integrated approach allowed for the first time to quantitatively characterize the transformation of asphaltene particles under the influence of low-frequency acoustic waves (5 kHz), including the disruption of their core and stabilization of the dispersed system.

“Our goal is not just to analyze, but to actively control the structure of asphaltenes in real time. We have proven that acoustic stimulation is an effective tool for destroying aggregates and stabilizing dispersed systems, especially at the late stage of field development,” said Mr Alfayaad.

The methodology has been implemented as a software package and has already received a certificate of state registration of the computer program. The scientific results have been published in leading specialized journals, including Russian journals from the VAK list and international Scopus Q1 journals.

Among the key results: reduction of the average core radius of asphaltene particles by 40 percent; increase in the number of dispersed structures by 30-50 percent; increase in the thickness of the solvate shell by four times, which enhances the stabilization of the system, the maximum effect is achieved in the temperature range of 20-60 degrees Celsius, at which the destruction of asphaltenes is most pronounced.

“The development is aimed at solving the industry’s key challenges – reducing oil viscosity, eliminating the colmatization of the porous medium and destroying stable emulsion structures. These processes are critical for improving production efficiency and stability of hydrocarbon transportation,” explained Dr Kemalov. “The principal difference of the proposed method is its ability to work with oil disperse systems of high complexity, where traditional approaches are ineffective”.

The method, he said, is based on a strictly verified engineering approach that provides accurate calculation and modeling of the behavior of asphaltenes and other high molecular weight components under conditions of acoustic impact.

“The software package can be adapted to real production conditions, can be easily integrated into existing field schemes and supports compatibility with modern digital platforms of the oil and gas industry. This makes the solution a promising tool for improving the efficiency of all stages of oil treatment, stabilization and transportation,” he stressed.

According to Professor Kemalov, the results not only demonstrate the effectiveness of wave action on the structure of dispersed oil systems, but also create a solid scientific and engineering basis for the formation of breakthrough technological solutions aimed at the development of heavy and hard-to-recover reserves. Of particular value is the possibility of integrating this methodology into existing field processes without the need for a radical restructuring of the infrastructure.

“This is the most important direction of oil industry development, especially in conditions of increasing complexity of geological sections and the need to increase oil recovery at minimum energy consumption,” he added.

The software system has been tested within the framework of a number of state projects, contests, and programs, including the program “Start-1” of the Innovation Promotion Foundation, federal initiative “Student Startup”, competition “50 best innovative ideas for the Republic of Tatarstan”, competition “1,000 best innovative ideas for the Republic of Tatarstan”, Engineer of the Year 2023 in the Republic of Tatarstan, as well as supported by the Academy of Sciences of the Republic of Tatarstan.

At the current stage, preparations are underway to implement the software solution in an international partner interested in the introduction of new generation wave technologies to intensify the production of hard-to-recover oil reserves. By the way, today the software product is already being implemented in the educational process of KFU, as well as in the real production conditions.