Gas-tight syringe developed by winner of Student Startup

Vladislav Chalin, KFU alumnus, Laboratory Assistant of the Laboratory of Enhanced Oil Recovery, is creating a promising model of a gas-tight syringe made of domestic materials; the funding is to be provided by Student Startup.

He will receive 1 million rubles to produce a pilot batch of syringes.

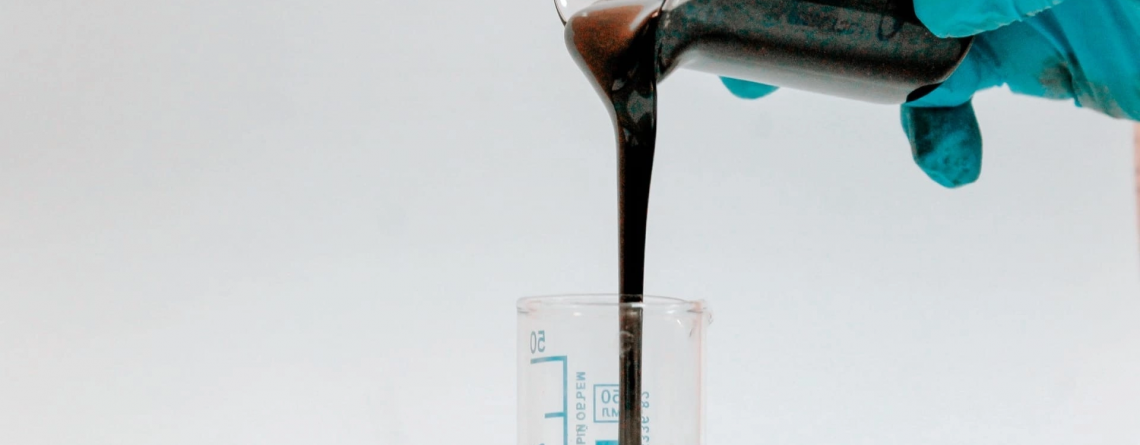

“In the laboratory, we perform many types of research, including analyzing the component composition of gases. This is important, for example, to understand the behavior of the reservoir system. For this purpose, a gas-tight syringe is used: a sample of the gas under study is taken into it, then the gas is injected into a chromatograph – special equipment for analyzing the component composition of substances, and we get detailed information about what our gas is,” said the winner.

The syringe developed at KFU is aimed at import substitution, strengthening Russia’s technological sovereignty, which means that it will be made exclusively from domestic raw materials, says Chalin. In particular, the plans include an acid-resistant housing with the ability to work with gases with high hydrogen sulfide content.

“It is possible to buy a syringe abroad, of course, but it will be time-consuming and expensive, so there was an idea to create our own competitive product,” he noted.

The developer also told about some characteristics of his device. The syringe will have absolute gas-tightness, i.e. the selected fluid will not be able to interact with the environment. In addition, the syringe’s heat-resistant and hermetically sealed plunger can be considered an advantage.

“Kazan University has amassed a great experience in the application of gas syringes, and the shortcomings of existing models have been identified. Now we have design documentation, drawings of the developed sample in hand. We are ready to start!” the young scientist shared his contentedness.

According to Chalin, the demand for laboratory instruments is quite high. Research laboratories and scientific centers specializing in gas chromatography need high-quality equipment. In an interview, the lab technician, who plans to continue his postgraduate studies, explained that the team is now focused on quality and demand. The project will be scaled up after the first pilot batch is produced.

Vladislav is being helped in his business initiative by his mentors and senior colleagues – his research supervisor, Lead Research Associate of Laboratory of Generation, Storage and Transportation of Hydrogen and Energy Carriers with Low Carbon Footprint Alexander Bolotov and Senior Lecturer of the Department of Petroleum Engineering Ilgiz Minkhanov.