Research

Technologies of non-traditional hydrocarbons

- Extraction of bitumen;

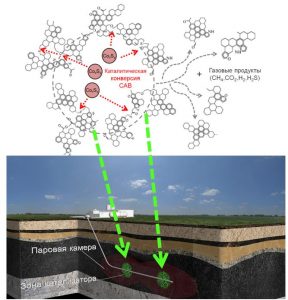

- Experiment in the autoclave of samples of oil and oil-saturated rocks;

- Determination of volatile oil hydrocarbons boiling up to 110ºС;

- Group composition (SARA-analysis of oil – the content of saturated and aromatic hydrocarbons, resins and asphaltenes). Oil bitumen. Separation method into four fractions GOST 32269-2013 / ASTM D2007-03;

- Calculation of the Colloidal Instability Index (CII);

- SARA analysis of oil micro-sample (less than 0.1 g). (content of saturated and aromatic hydrocarbons, resins and asphaltenes). Oil bitumen. Separation method into four fractions GOST 32269-2013 / ASTM D2007-03;

- Fractional distillation of oil and oil products. GOST 2177-99;

- Isolation of insoluble organic matter of shale rocks (kerogen);

- Study of the composition of gaseous products by gas chromatography;

- Determination of the composition of volatile fatty acids in water (VFA);

- Determination of paraffin content in oil. GOST 11851-85;

- Determination of thermal conductivity (thermal conductivity coefficient) of oil (based on density and solid paraffin content (GOST 11851-85)). Dependence of thermal conductivity on temperature with a step of 10° in the range of 10-60 °C (6 points);

- Melting point of paraffins. GOST 23683-89;

- Determination of the content of chloride salts. GOST 21534-76;

- Determination of the acid number of oil. GOST 5985-79;

- Determination of the content of organochlorine compounds in oil. GOST R 52247-2004.

- Oil and oil products. Density determination methods. GOST 3900-85.;

- Determination of the heat capacity (heat capacity coefficient) of oil using the Watson-Nelson formula (taking into account density). Dependence of heat capacity on temperature with a step of 10° in the range of 10-60 °С;

- Thermal expansion coefficient (taking into account density. Dependence of the thermal expansion coefficient on temperature in 10° increments in the range of 10-60 °С (6 points);

- Determination of iron sulfide;

- Determination of viscosity at different temperatures. Viscosity versus temperature in 10° increments in the range of 10-60°C (6 points);

- Kinematic viscosity, GOST 33-2016;

- IR spectroscopy. IR spectroscopy + decoding of functional groups;

- Determination of sulfur content in oil GOST 32139-2013;

- Ash content;

- The pour point of oil. GOST 20287-91;

- Determination of mechanical impurities. Oil, oil products and additives GOST 6370-83;

- Oil and oil products. Method for determining the water content (according to Dean-Stark) (with Amendment, with Amendment No. 1) GOST 2477-2014;

pH determination; - Determination of particle size distribution by dynamic light scattering;

- Surface/interfacial tension at s.u.;

- Surface/interfacial tension. In thermobaric conditions: temperature range: from +10°C to +200°C; pressure range: from 1 to 690 bar;

- Contact angle of wetting on a rock sample during visual observation of the behavior of materials (video and photo are saved) at s.s.;

- The contact angle of wetting on a rock sample by visual observation of the behavior of materials (video and photo are saved). In thermobaric conditions: temperature range: from +10°C to +200°C; pressure range: from 1 to 690 bar;

- Determination of wettability by the method of Amott.;

- Determination of wettability by the Amott-Garvey method;

- Determination of the dissolution kinetics of a carbonate rock sample in HCl (12%). Reading the kinetic curve for 6 hours.

- Contact angle measuring device under pressure DSA100 (2015). The device allows you to determine the surface / interfacial tension and the contact angle at pressures up to 70 MPa, as well as visually observe the behavior of materials under these conditions. Temperature measuring range: from +10°C to +400°C. Availability of automatic function for sequential measurement of surface free energy;

- 300 ml autoclave reactors Parr Instruments (USA) 2 pcs. Allows modeling of reservoir processes. Temperature range: room. – 350. Pressure range: atm – 120 bar;

Aromatek Crystal 5000 (2017). The instrumentation complex was specially designed at the Khromatek enterprise to solve the problems of analyzing the complex composition of hydrocarbon mixtures. Allows you to analyze the composition of gaseous products directly during the simulation of the thermocatalytic process on the Parr Instruments autoclave; - Zeta-Aps Particle Size and Zeta Potential Analyzer (2014). The device allows you to determine the distribution of particles by size and their zeta potential, pH of the medium, electrical conductivity. The device is based on the use of ultrasonic radiation as a working one, which makes it possible to use it for the analysis of opaque dispersed media, such as oil;

- The laboratory has a full range of general laboratory equipment (LOIP LF-5/13-V2 muffle furnace with programmable temperature controller, LOIP LF-120/300-VS2 oven with programmable temperature controller, Pulverisette 6 planetary monomill, Fungilab ALPHA L rotational viscometer, Hei laboratory rotary evaporator -VAP, etc.)

Aleksey Vakhin

Aleksey Vakhin